Reshoring Production Minimizes Risk. Is Your Supply Chain Still Sourcing Critical Parts From Overseas?

During the uncertainty of negotiations between the ILA and USMX, Catalyst received questions from concerned clients about our ability to deliver components on time. Fortunately, they were in good hands.

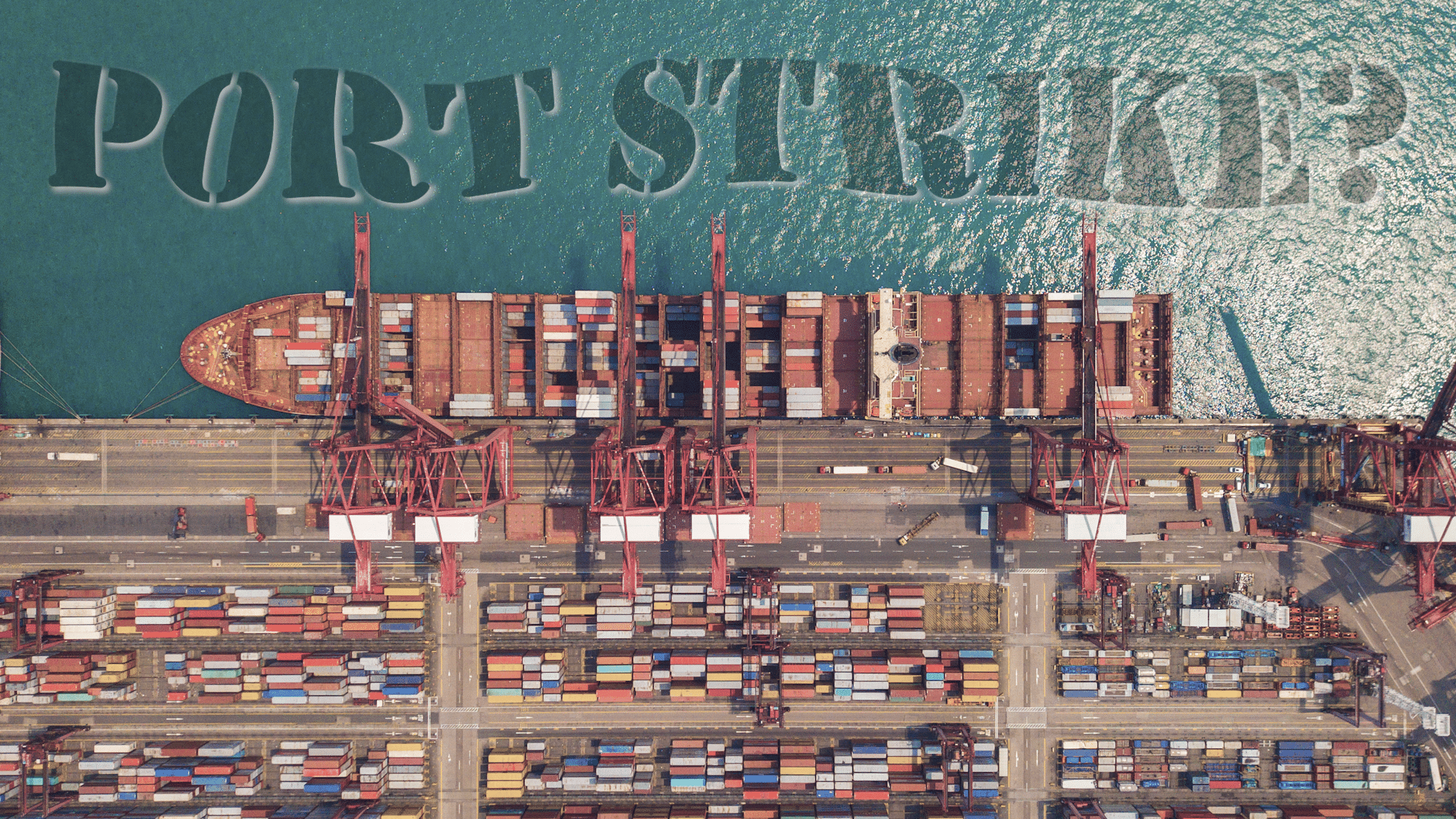

The ILA strike in October of 2024 disrupted operations at 36 ports from Maine to the Gulf South during a 3-day period. The ILA reportedly pulled out of talks with USMX in November with both sides standing firm until an agreement was reached on Wednesday, January 8th. As Flexport CEO, Ryan Peterson discussed on CNBC, many companies were feeling the pressure.

It seems that for now, the prospect of a protracted disruption of shipments has been put to rest. As Medora Lee of USA Today notes, there will still be a financial impact felt by importers of foreign components and products due to the negotiations:

“… a tentative agreement for a 62% wage increase for ILA members over the next six years … USMX said ILA workers would continue to work under their current contract until the new six-year contract can be ratified.”

Catalyst clients are relieved to learn that our operations are purposely designed to be independent of the volatility in international trade. Are your overseas supply chain operations still vulnerable to the next inevitable rate hike, contract dispute, natural disaster or period of political turmoil?

Tipping The Scale

It has been our position for years that the supply chain nightmare during the pandemic serves as a wake-up call for companies that are heavily reliant on foreign suppliers. Political tensions continue to flare up around the world adding significant risk to gambling on stable global trade for the foreseeable future. The labor dispute issue at east coast ports added another layer of concern to the equation. When combined with the prospect of much higher tariffs on products entering the country, companies are quickly reshoring manufacturing as the scales tip in favor of reliable and increasingly cost-effective domestic production.

A Reliable Reshoring Solution

Catalyst recognizes the unprecedented sourcing challenges that companies are facing at the moment. Fortunately, a partnership with Catalyst presents a quick and reliable supply chain solution.

Our clients enjoy the peace of mind knowing their intellectual property is protected by an NDA. All services are completed at our Indianapolis facility, minimizing exposure, claiming full market share potential, and reducing risk. It makes sense to secure a domestic source for critical parts as an emergency backup strategy or transition plan within a larger reshoring effort.

Throughout our 25-year history, Catalyst has insulated our clients from the volatility of global trade. There is no doubt that we can do the same for your operations. Gain the Catalyst advantage in your reshoring efforts! Contact Catalyst for expert, domestic plastic design and manufacturing services you can rely on.