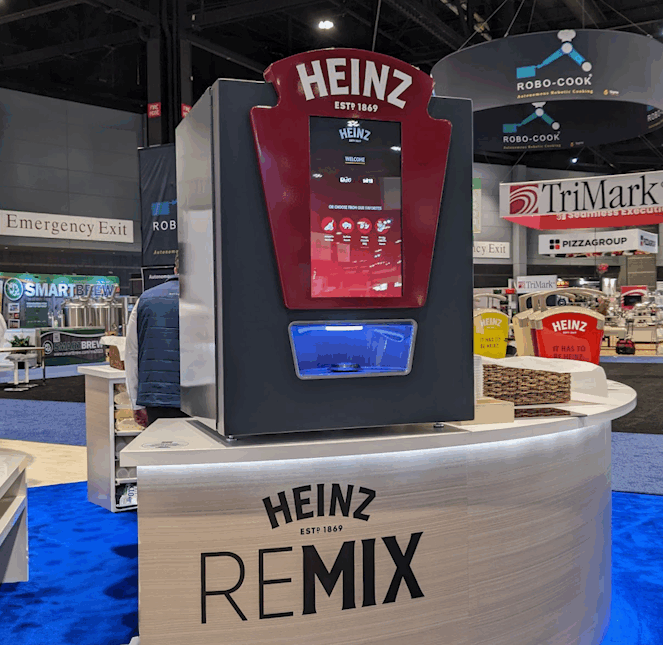

Case Study: Kraft Heinz REMIX

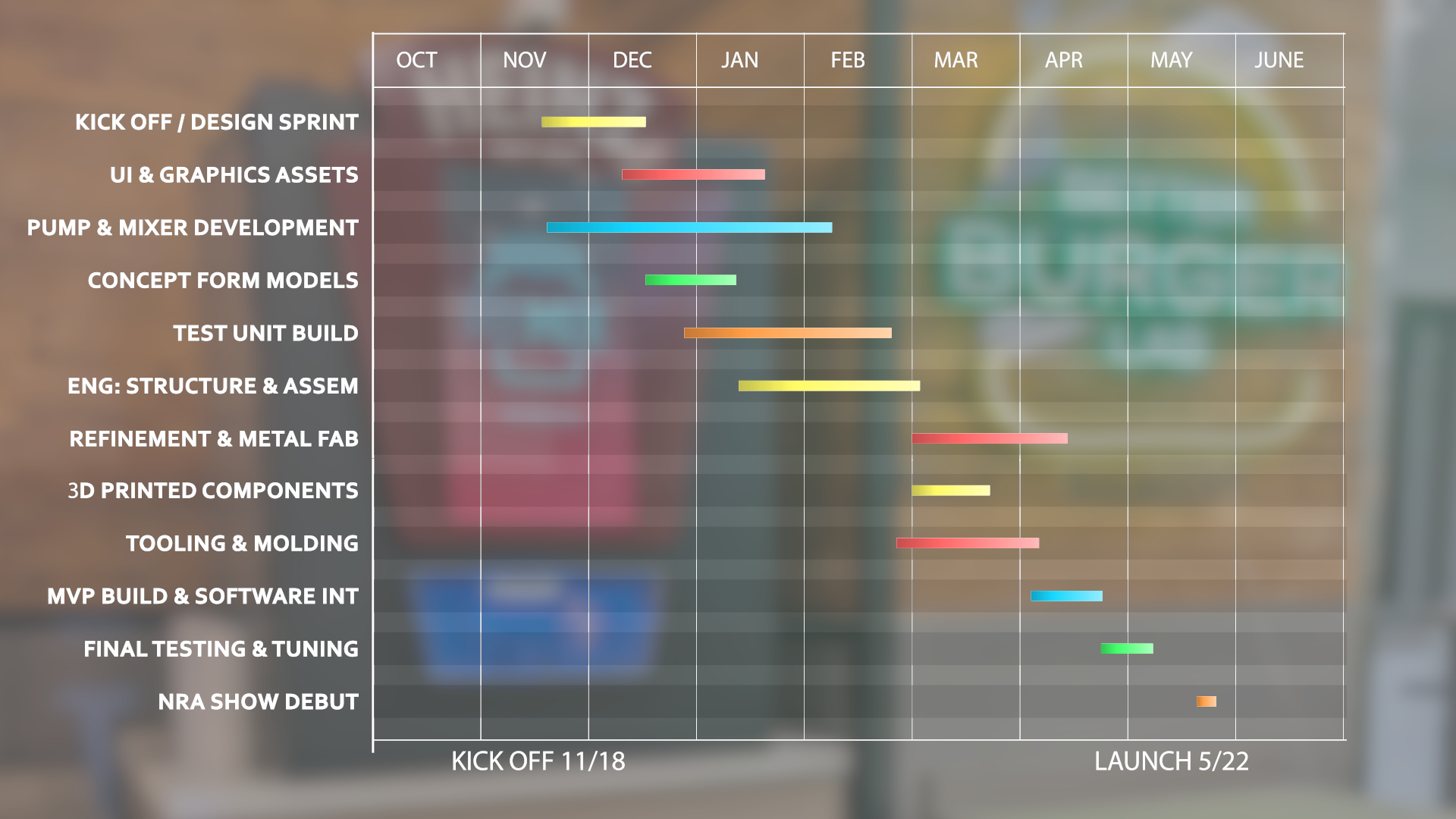

Developing a complex, customer-facing product is a formidable challenge, even for a global brand with deep resources. Now add a hard launch deadline tied to a major trade show reveal, and the stakes rise dramatically. Unforeseen delays can derail the best laid plans. That’s where Catalyst comes in—providing project acceleration, engineering precision, and cross-functional coordination needed to meet ambitious timelines without sacrificing quality.

One such success? The Heinz REMIX.

Reimagining Flavor, One Touchscreen at a Time

Heinz is one of the most recognized and trusted names in food- from diners and food trucks to upscale restaurants. But tradition alone doesn’t keep a brand relevant. Heinz continually looks for ways to modernize the consumer experience, and the Heinz ReMix is a prime example of innovation done right.