THE HIDDEN IMPLICATIONS OF OUTSOURCING PRODUCT PRODUCTION TO LOW COST COUNTRIES

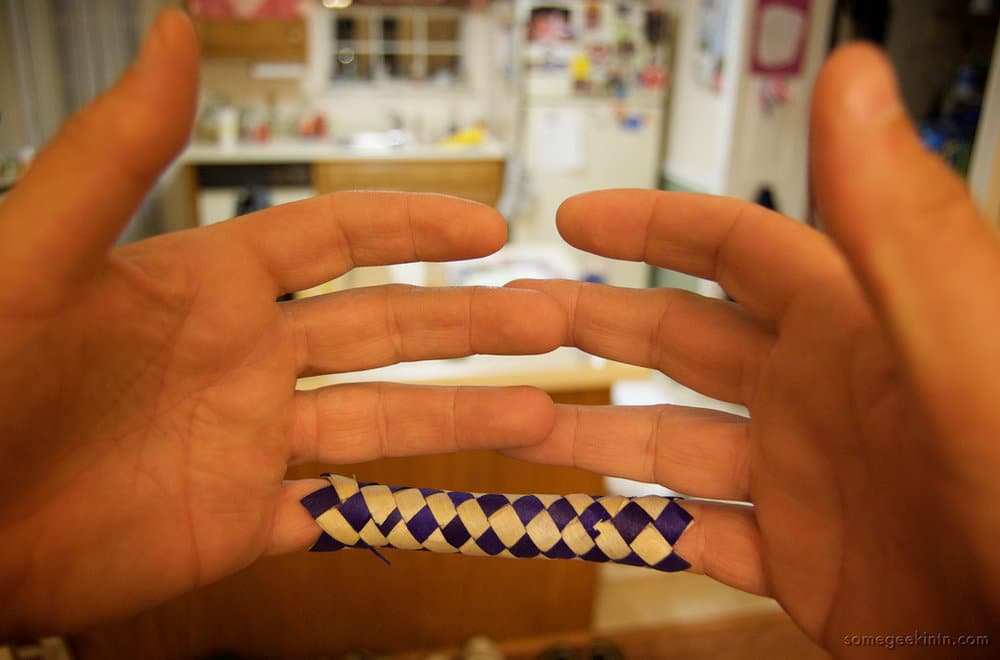

A large part of Catalyst’s business is tooling rapid, prototype, and bridge plastic injection molds for our clients. In fact, few vendors who specialize only in tooling can consistently build the complex plastic injection molds that we do in the lead time or price that we do it. But, in quoting situations sometimes we hear “I have a quote from China that is less than yours”. When we hear this, we think of the little Chinese finger puzzles that are popular at kid’s birthday parties. The key is to relax, think about why you are trapped, and then escape.

Our response is usually something like “Wow, that’s impressive…and in the same 14 days we quoted to do it?”

“Well, no. They want 8 weeks for the tools and 2 weeks for shipping. But I am willing to wait for that kind of savings.”

Ah, there it is…”the savings”. If that Chinese vendor found through a Google search is who they say they are and does exactly what they say they will, then yes, “the savings” will be significant. But what if they are not? What if that impressive machinery and army of well-trained, uniformed workers shown on their website are not really there? How would a potential customer know?

Let’s say that the company does exist and it is an impressive facility just like the website shows. They are given a credit card number and sent 3D models, material specs, and quality expectations of the part to be tooled. (This may require numerous emails and late night/early morning phone calls—because of the time difference). So all we have to do now is wait 10 short weeks for the parts.

If the parts arrive on time and they are perfect, then all is well—the savings are realized!

But are they really savings?

LOST TIME: THE HIGH COST OF FOREIGN PROTOTYPING SERVICES

Keep in mind that during the product design and development stages, sales are zero and profits are actually negative because the predicted future profits are being invested in the product development. The longer it takes to develop the product and begin production/distribution, the lower the profits will be over the lifetime of the product. Saving a few thousand dollars by working with an overseas vendor, might well cost a hundred-fold in lost revenues by a delayed market entry.

And, what if there are issues with the tooling or parts? Trying to communicate engineering fixes/changes, negotiate additional fees, explaining quality and material spec issues and waiting for new samples will all add time and cost to the process. A single trip to visit the vendor may even be required which will cost thousands of dollars, negating most of the cost savings.

The fact is building tools and molding parts in low-cost producing countries is usually not a seamless process and can have a number of challenges. Consider the following:

- Overseas manufacturing is usually only efficient if the throughput volumes are high. Low volume products are generally not cost effectively produced overseas.

- The agility of being able to exploit lucrative special/custom applications is lost in overseas manufacturing when trying to quickly respond to an opportunity in the market.

- Transferring a new product to overseas manufacturing is difficult especially if the overseas manufacturer was not involved in the development. Simply taking a new product design and sending it to an offshore manufacturer usually creates chaos in the initial production roll-out. This usually requires extensive, costly travel of key personnel.

- There is little to no protection for intellectual property (IP) when using an overseas manufacturer. Unless, there is an existing relationship with the vendor, there is nothing to stop them from taking your product design and selling it across the world if they like.

CHOOSE A USA BASED COMPANY THAT EXCELS IN PRODUCT DESIGN, PRODUCT DEVELOPMENT, AND RAPID PROTOTYPING SERVICES

Catalyst is one of the few (if not the only) product design company with an entire engineering support team, tooling, molding, and assembly operation in-house. We offer this service to both protect our client’s valuable intellectual property and to help speed their products to market. We work with many clients that have impressive infrastructures in low-cost countries to support their production tooling and plastic injection molding needs. When developing new products, they often first build rapid or prototype tooling in the US. This way, they can then check form/fit/functionality, make engineering changes, sample different resins, and dial the part geometries in. Once satisfied, they send samples, part databases, and tool designs overseas. Often, we are asked to consult with their overseas vendors to help in the transfer of information. An added benefit is that while production tools are being built, the rapid tooling can be used as “bridge tooling” to ramp up early production and capture the market entry.

Remember, it is often easy to get caught up in the potential savings offered by low-cost producing countries. Be sure to consider all costs involved, including hidden and opportunity costs, before making that decision—otherwise it may be more than your fingers that feel trapped.