At Catalyst, we’ve always said that the mark of a truly comprehensive product development firm is the ability to create a rough concept and then deliver a refined production-quality product.

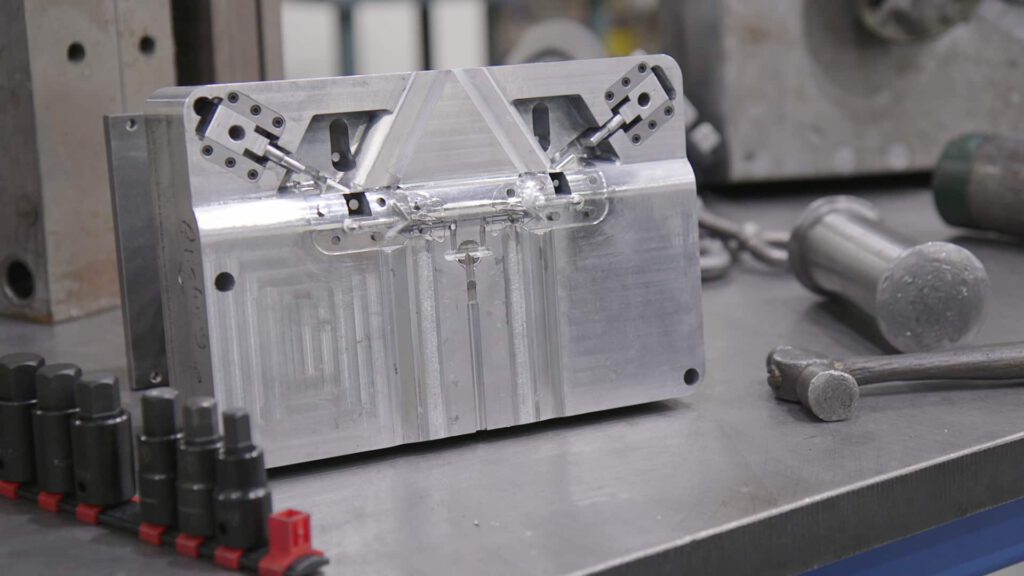

That means we work in virtually any material or manufacturing process a project requires. Housings for electronics and complex assemblies need specialized knowledge to be developed efficiently. So, plastic injection molding isn’t all we do here, but we pride ourselves on being true experts when it comes to creating high-quality plastic components from scratch.

As a premiere industrial design firm, we recognize the importance of refined aesthetics in new products. Paramount among a product’s features is the ergonomics, fit, finish and functionality. Today, we are going to focus on an additional important aspect … custom color.

A custom color is often central to a brand’s identity and connection with their customers. Great care is taken to define the exact color value whether it’s for a farm tractor, power tool or tricycle. So how can Catalyst guarantee our clients receive accurate custom color components? It turns out that the process is a blend of art and science.