Our nation’s backbone is based on an entrepreneur’s vision to create their dream into reality. Catalyst Product Development has guided many first-time entrepreneurs through this process over our 20-year history. Our entrepreneurs arrive packed with passion for their idea which feeds our team’s expertise with extra excitement during the new product development journey.

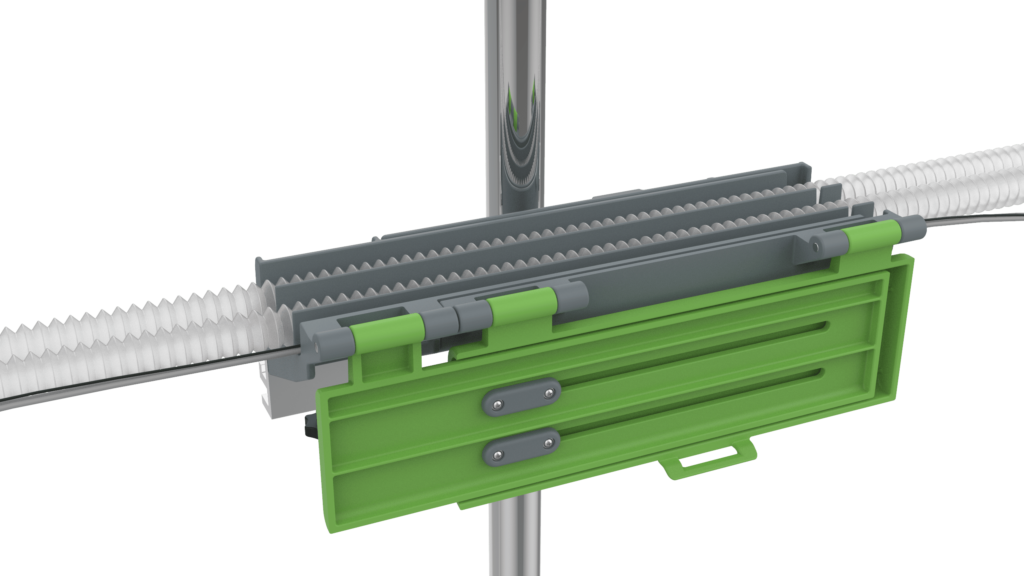

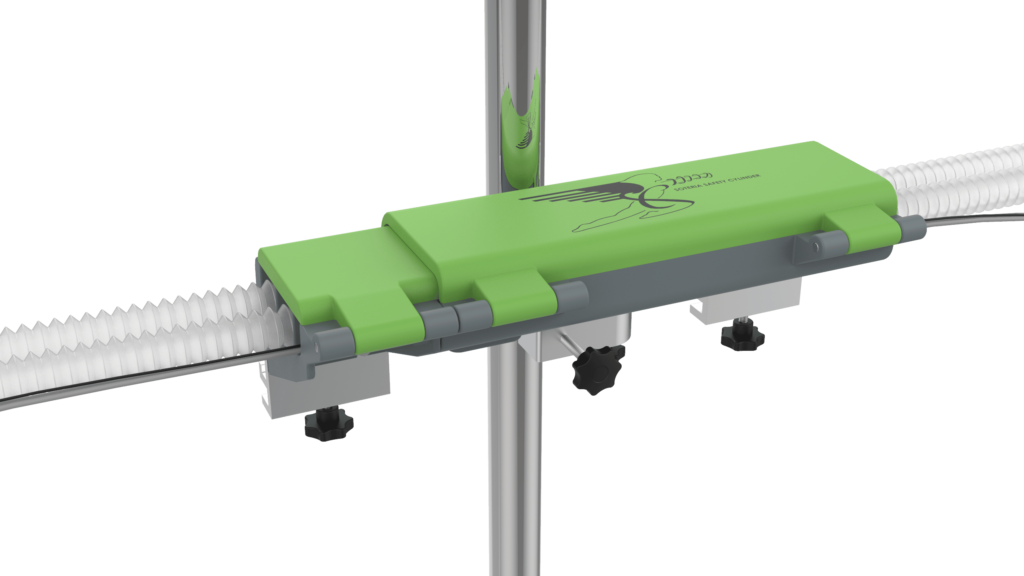

Our latest driven Entrepreneur, Sheila Ray, is Certified Registered Nurse Anesthetist and researcher who saw a need to develop a medical device to control the ventilation tubing and lines during an operation or an ICU stay. When we first met Sheila, she had fought through the patenting process, won US patent protection, and had a very nice first round prototype concept. She was looking for a quote for injection molding to move the program into the next phase of development. Unfortunately, the original design was not capable for production and the Catalyst Team re-imagined the design into something that could be manufactured. This is often a stumbling block when choosing a design/engineering only firm whose main focus is to create a great design; they often fail to consider the end product manufacturing and production requirements.

Catalyst Product Development has the unique business model that incorporates industrial design, engineering, prototyping, injection mold tool making and injection molding under one roof that produces a blending of expertise. Our team gleams insight from each other’s know-how and challenge the status quo to work through potential manufacturing and production challenges up front through great thoughtful design.

For Sheila’s project, the Catalyst team had to re-engineer her initial concept design, making it manufacturable for the injection molding process. This can be a disappointing setback for first time entrepreneurs when they discover they need to revisit the engineering phase. When doing so on Sheila’s project, the Catalyst team was able to problem solve and provide manufacturing solutions that reduced the costs. The need to core out the base component of the product led to simplifying the lid design, ultimately saving cost on the overall product. Finally, Catalyst was able to integrate a second attachment function for use on an IV pole, which expanded her product’s functional use.

We invite you to watch Sheila’s video explaining the product, and the problem she wanted to solve to make a safer operation setting. Please explore “Create the Future Design Contest” and support our entreprenuer with your vote.